Shackles

Subcategories

-

-

Clearance - While Supplies Last!

1/4" Type 304 Stainless Screw Pin Anchor Shackle (WLL 0.50 ton)

1/4" Type 304 Stainless Screw Pin Anchor Shackle (WLL 0.50 ton)116-304-SHACKSPA0250

-

-

1" Screw Pin Anchor Shackle (WLL 8.50 ton)

1" Screw Pin Anchor Shackle (WLL 8.50 ton)115-SHACKSPA1000

-

1" Twist Lock Alloy Shackle (WLL 12.50 Ton)

1" Twist Lock Alloy Shackle (WLL 12.50 Ton)340-11-TLS1

-

1" Type 304 Stainless Screw Pin Anchor Shackle (WLL 5 ton)

1" Type 304 Stainless Screw Pin Anchor Shackle (WLL 5 ton)116-304-SHACKSPA1000

-

1" Type 316 Stainless Screw Pin Bow Shackle (WLL 6000 lbs)

1" Type 316 Stainless Screw Pin Bow Shackle (WLL 6000 lbs)341-S0116-0025

-

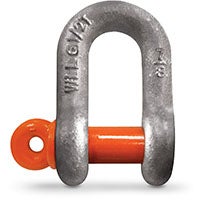

1" Type 316 Stainless Screw Pin D Shackle (WLL 6000 lbs)

1" Type 316 Stainless Screw Pin D Shackle (WLL 6000 lbs)341-S0115-0025

-

1-1/2" Screw Pin Anchor Shackle (WLL 17 ton)

1-1/2" Screw Pin Anchor Shackle (WLL 17 ton)115-SHACKSPA1500

-

1-1/4" Screw Pin Anchor Shackle (WLL 12 ton)

1-1/4" Screw Pin Anchor Shackle (WLL 12 ton)115-SHACKSPA1250

-

1-1/4" Twist Lock Alloy Shackle (WLL 18 Ton)

1-1/4" Twist Lock Alloy Shackle (WLL 18 Ton)340-11-TLS125

-

1-1/4" Type 316 Stainless Screw Pin D Shackle (WLL 9000 lbs)

1-1/4" Type 316 Stainless Screw Pin D Shackle (WLL 9000 lbs)341-S0115-0032

-

1-1/8" Screw Pin Anchor Shackle (WLL 9.50 ton)

1-1/8" Screw Pin Anchor Shackle (WLL 9.50 ton)115-SHACKSPA1125

-

1-3/4" Screw Pin Anchor Shackle (WLL 25 ton)

1-3/4" Screw Pin Anchor Shackle (WLL 25 ton)115-SHACKSPA1750

-

1-3/8" Screw Pin Anchor Shackle (WLL 13.50 ton)

1-3/8" Screw Pin Anchor Shackle (WLL 13.50 ton)115-SHACKSPA1375

Shackles

- Your Destination for Shackles

Are you looking for load-bearing shackles for inline connections or overhead lifting? Your search ends here! We offer a wide variety of shackles from top domestic brands as well as import shackles. You'll find shackles for rigging, construction, marine, oil and gas, agricultural, theatrical, transportation, etc. We have options for every working load and every budget.

Browse through our wide selection of shackles. We carry anchor and bow shackles, the most popular shackles in use today. We also carry chain and "D" shackles, wide body shackles, subsea shackles, and web sling shackles. You'll find styles with the three main pin types: screw pin, round pin, and bolt type.

We proudly offer shackles from domestic market-leader brands Crosby and Columbus McKinnon. They come in hot dip galvanized, painted, or black powder coated finishes. We carry Suncor Stainless brand shackles for marine or culinary jobs. Our imported shackles also come in a variety of materials and finishes.

- What is a Shackle?

Simply put, a shackle is a connector with a specific shape and set of components. All shackles have four definitive parts. The bow is the curved part opposite the pin that takes the weight of the load. The ears are part of the shackle body. They support the pin, and the pin is usually a steel bolt that spans the two shackle ears. The shoulder is the part of the pin that makes contact against the ear when fully threaded.

The shape of the shackle determines its use. The most common shackles are anchor shackles and bow shackles. They have a rounded "O" shape and can accommodate many connections because of this. Other common shackle types are chain shackles and "D" shackles. These have a narrower "D" shape, and because of this should never be side loaded.

Shackle uses are also determined by the type of metal and the manufacturing process. Carbon steel or alloy steel shackles withstand overhead lifts and the heaviest workloads. Forged shackles are stronger than poured shackles. A job spec may call for one or the other. Galvanized shackles have a zinc oxide coating to resist corrosion and deterioration.

Stainless steel shackles offer the highest levels of corrosion resistance. Some are even food grade and marine grade. Type 304 and Type 316 stainless shackles meet FDA regulations. Type 316 is a far superior choice when it comes to salt water and chemical resistance.

- Shackle Pin Types

There are three main pin types: screw pin, round pin, and bolt type. Screw pin shackles are convenient because they are easy to connect and disconnect. But, because of this, they are not for permanent installations. Round pin shackles have an unthreaded pin secured by a cotter pin. They are popular in tie-down applications used by the trucking and transportation industries. They are never used for overhead lifting or where side loading may occur. Bolt type shackles are more secure with a bolt and nut securing the shackle alongside a cotter pin. These can work in place of both screw pin and round pin shackles. Because of the tightening nut and cotter pin these do not need tightening for every lift. They are for more permanent and long-term installations.

- Not sure which shackle is right for your job? Our customer service team is here to assist you.

- Don't see what you need on our site? Call us or email us! If it's available, we will source it for you.

- Need your shackles in a hurry? Contact us with your timeline and we will fill your order as quickly as possible.